Brehob is proud to sell and service Quincy’s oil-free air compressors from 2 to 400+ hp. Avoid oil contamination issues and stay up and running with oil-less products from the top brand in the business.

ISO 8753-1

Class 0 Certification

When it’s essential to avoid contamination by even the smallest quantities of oil, choose Quincy oil-free air compressors. Meeting the Class Zero standard means these air compressors produce the best air quality possible, while also providing top class performance, low maintenance and operating costs, premium efficiency and quality, and outstanding reliability.

QUINCY OIL-FREE SCROLL COMPRESSOR

QOF 2-30 hp Oil-Free Scroll Compressor

Features

- Scroll technology offers optimum performance for applications requiring 2-30 hp

- SO 8753-1 Class Zero certification means these air compressors meet the highest standard for air quality

- 116 to 145 psi pressure rating

- 4 to 86.5 CFM capacity

- 230, 400, 460V (one and three phase, depending on selection)

- Sound levels as low as 53 dBA

- High-efficiency IE3 motor

- Corrosion resistant materials

- Low vibration

QUINCY OIL FREE ROTARY TOOTH AND SCREW COMPRESSORS

QOFT 20-75V

Features

- Rotary tooth technology offers optimum performance for applications requiring 20-75 hp

- ISO 8753-1 Class Zero certification means these air compressors meet the highest standard for air quality

- Inter-cooler & after-cooler

- Two stage tooth airend creates lower energy consumption

- Sound insulated canopy means no separate compressor room is required

- Induction motor requires no lubrication, eliminating service requirements

- Combined air filter and silencer

- Integrated VSD inverter

- Q-Control Touch control and monitoring system

- Electronic water drain provides constant removal of condensate

QOF 75-400

Features

- Rotary screw technology offers optimum performance for applications requiring 75-400 hp

- ISO 8753-1 Class Zero certification means these air compressors meet the highest standard for air quality

- Highly efficient inlet filter means minimum intake losses

- Advanced Q-Control monitoring system

- High precision gears AGMA A5

- Superior airend bearings with high stability under varying load conditions

- Water separator that efficiently separates condensate from compressed air

- World class oil-free compression rotors

- Totally enclosed fan-cooled motor

- Aluminum alloy or stainless steel coolers

- Air-Cooled and Water Cooled available

WHICH INDUSTRIES NEED OIL-FREE COMPRESSORS

In some industrial environments, oil-free compressed air is critical to avoid costly production downtime and product damage. When cleanliness matters and risk tolerance for contaminants is low, oil-free compressors keep your product and reputation intact.

Any industry that values clean air and low costs benefits from oil-free products — but there are particular advantages for the following fields:

Food & Beverage

Cleanliness is crucial in avoiding contamination in food and beverage products, including the brewing industry. Oil-free compressors ensure 100% clean, oil-less compressed air.

Medical & Pharmaceutical

Every step of the process counts (and is subject to review) when it comes to pharmaceutical and medical applications. Keeping risks as low as possible means keeping trace contaminants out, making oil-free compressed air critical.

Natural gas

Fume elimination, gas transfer, and vapor recovery all benefit from compressed air.

Energy exploration

The dependability and low maintenance needs of oil-free compressors make them ideal for remote energy exploration, where downtime has big costs.

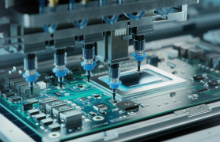

Electronics

Moisture-and-oil-free compressed air protects fragile instrumentation, necessary for printed circuit board cleaning and other applications.

Aerospace

Clean, compressed air has many applications in the aerospace industry, from launching rockets to controlling contamination.

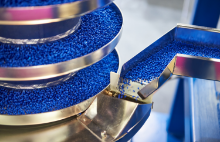

Plastics

Constant and steady compressed air keeps processes moving in plastics manufacturing. The increased dependability of oil-free air compressors prevents unexpected air losses that can bring down operations.

Textiles

Air-jet looms and spinning machines require clean, uncontaminated compressed air to avoid production loss and fabric staining.

Plumbing

Clean, oil-less air is required to test the water pressure of piping systems.

Painting

Oil-free compressors speed up the painting process without contaminating paint with oil.